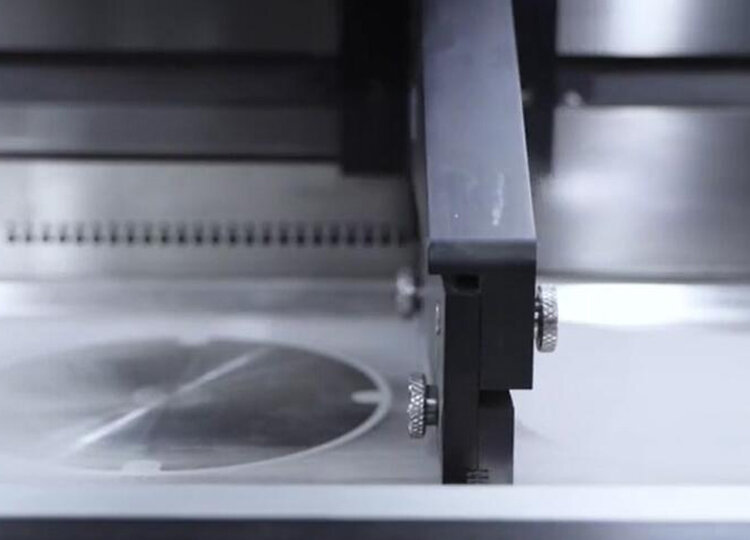

EP-M150 Metal 3D Printer

The EP-M150 uses a fiber laser to directly melt elemental or alloy metal powders to form complex structures and parts. The EP-M150 has a variety of small metal applications in fields such as, material development, medical implants, dental, and jewelry.

Features

High Precision Printing Quality & High Efficiency

∙ Small laser facula and thin layer thickness guarantee more precise printing quality.

∙ Intelligent powder coating method and faster scanning speed.

∙ Unique scanning path and oxygen control assure high-quality printing.

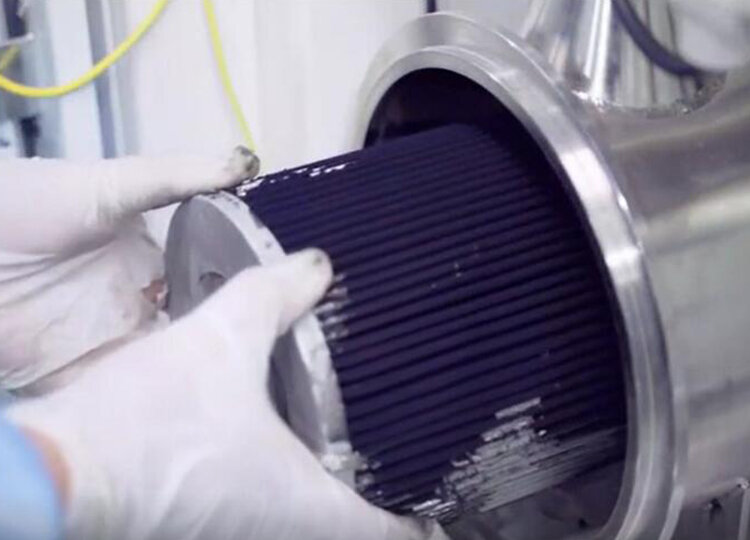

Low-cost operation

· 500 crowns printed using only 1KG of powder

· Improved powder feeding and sieving system enables high material utilization

· Gas consumption≤<0.2L/min(0.3±0.1MPa) (Printing period)

· Optimized chamber structure and excellent sealing properties minimize gas consumption

Easy Maintenance

· Intuitive user interface

· Optimized structure design for easier maintenance

High Safety

· Integrates more than 10 security technologies

· Working environment and real-time gas monitoring

Specification

Build Volume

Φ150mmx120mm

Laser

Fiber laser,200W/500W(optional)

Optical System Configuration

Single laser system / dual-laser system (optional)

Spot Size

40~60μm

Max Scan Speed

8m/s

Layer Thickness

20-100μm

Max Build Speed

12cm³/h(single laser system )/ 18cm³/h(dual laser system )

Material

Titanium Alloy, Aluminium Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc.

Power

220V,12A,50~60Hz,3.5kW

Gas Supply

Ar/N₂

Oxygen Content of Chamber

≤100ppm

Dimensions (W*D*H)

1750*799*1828mm³

Machine Weight

Around 900kg

Control Software

Eplus3d Print Software

Input Data Format

STL or other convertible file

Please contact us before order it.